Surface analysis (routine testing of non-magnetic samples)

S$xxxSurface analysis (magnetic sample, standard testing)

S$xxxArgon ion cleaning +standard testing

S$xxxValence band spectra (VBS)

S$xxxAuger electron spectroscopy (AES)

S$xxxUltraviolet photoelectron spectroscopy (UPS)

S$xxxEtching +standard testing

S$xxxTesting Description

X-ray photoelectron spectroscopy (XPS), also known as electronic spectroscopy for chemical analysis (ESCA), is a technique for analyzing the chemical properties of the surface of materials. XPS can measure the element composition, empirical formula, chemical valence state and electronic state of the material. Excite the solid surface with a beam of X-rays, and measure the kinetic energy of electrons emitted within 1-10 nm from the surface of the analyzed material to obtain the XPS spectrum. By counting the excited electrons exceeding a certain kinetic energy, the photoelectron spectrum can be obtained. The peaks appearing in the photoelectron spectrum are electrons with certain characteristic energy emitted from atoms. The energy and intensity of the photoelectron peak can be used for qualitative and quantitative analysis of all surface elements (except hydrogen). XPS test covers: conventional full spectrum narrow spectrum test, Auger spectrum, valence band spectrum, etching, mapping, Auger peaks, UPS, Argon cleaning, ARXPS, ISS, REELS etc.

1. Valence state and semi-quantitative analysis of test elements (except H and He elements);

2. Signals may NOT be detected on the elements less than 5wt%.

3. Samples containing Fe, Co, and Ni are considered magnetic samples.

4. Rare earth elements need to provide the test range, which may deviate from the default range of the instrument. Without special instructions, the default is to use a monochromatic Al K alpha source (Mono AlKa) with an energy of 1486.6eV

5. The samples can be cleaned and etched with argon ions (the depth of etching and the charging standard depend on the situation, you can contact our technical staff before ordering).

6. Powder samples can only be etched within 10s (about 2.9nm) 7. If the sample does not contain carbon or the surface has high tendency for absorption, you can choose “argon ion cleaning + routine test”, the test effect is relatively better.

Sample requirements

1. Powder sample: Please provide minimum 30 mg in a tube to minimize wastage during sample transfer.

2. Bulk / Film sample: Size within 5 × 5 × 3 mm (Length x Width x Thickness).

3. Liquid samples must be prepared on a substrate before sending over. Reference method: drop the sample on a clean substrate such as aluminum foil or silicon wafer and dry them to form a liquid film. You may need to repeat the dropping and drying 3-5 times, so the samples are sufficiently covering the substrate.

4.The material must be non-radioactive, non-toxic, non-volatile substances (such as elemental Na, K, S, P, Zn, Se, As, I, Te, Hg, etc.);

3. Samples containing elements such as S, F, I, Br, Hg, Cl, P cannot be tested. For special requirements, please contact us before ordering.

4. Sample packaging requirements: vacuum seal the samples to reduce the sample contamination, which will affect the test of certain elements, such as common C and O.

5. Samples cannot be recovered and returned post XPS test. As the XPS test requires samples to be fixed on the sample stage with conductive glue.

Examples

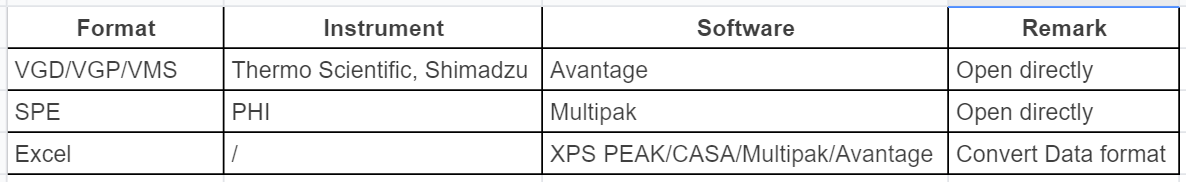

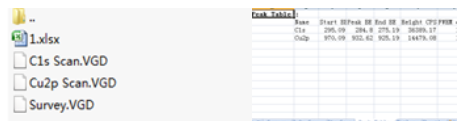

1.Thermo Scientific K-Alpha Instrument provides the following data files

The test results are given in VGD format and Excel format test results. Excel format files are drawn with ORIGIN software; VGD format files can be opened with Avantage analysis software.

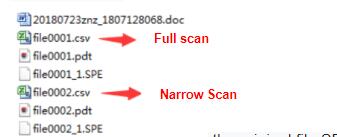

2. PHI data files

The test results are given in the original file SPE format and EXCEL format. EXCEL format files are drawn with Origin software; SPE format requires software Multipak to open

FAQs