-80°C (inclusive) - room temperature test temperature points

S$133/pointTest temperature points from room temperature to 400°C (inclusive)

S$75/point400℃-800℃ (inclusive) test temperature points

S$133/point800℃-1200℃ (inclusive) test temperature points

S$211/pointTesting Description

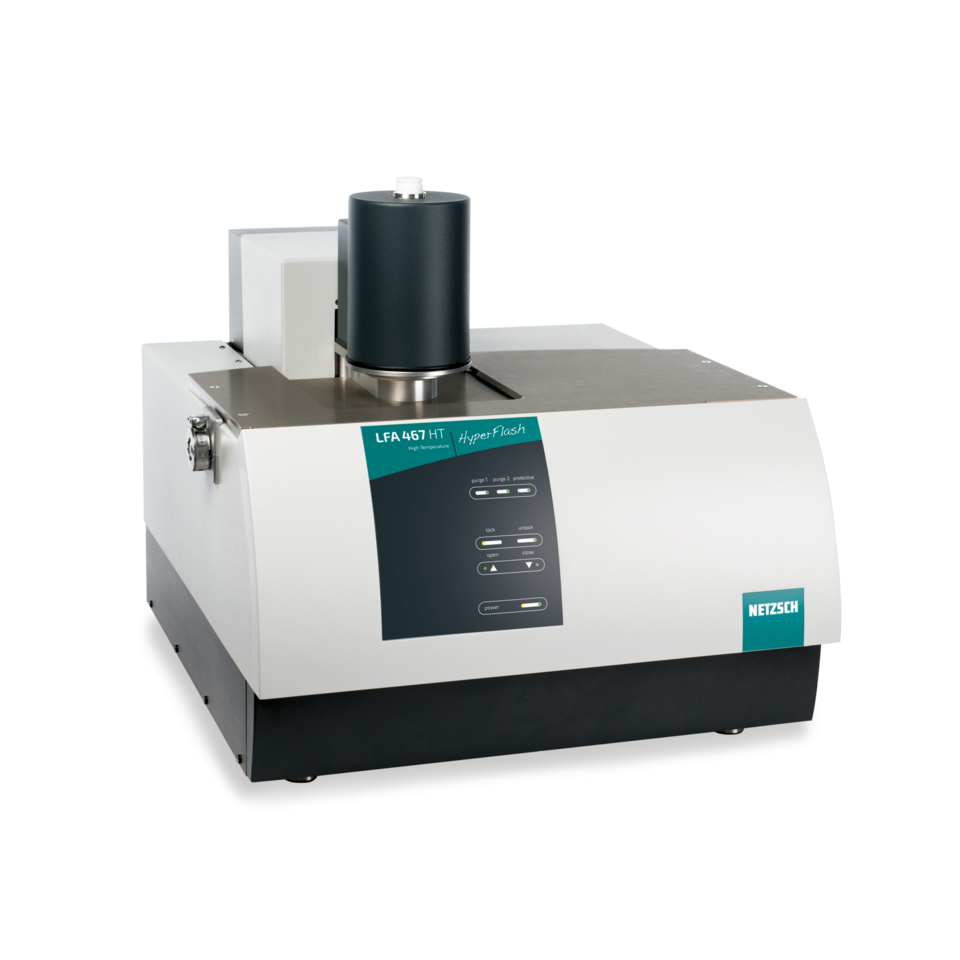

The Laser-Flash method or Laser-Flash-Analyser (LFA) is based on the rise of temperature on one side of a prepared test sample when it is heated by a short laser pulse from the other side. The energy of such a pulse is around 15 J. The temperature increase caused on the sample surface then propagates as a kind of heat wave through the sample until it is detected on the opposite side by an infrared measuring device. The sample itself can be heated to different temperatures in an furnace. In this way, the dependence of thermal conductivity on temperature can be examined.

Following materials can be tested by LFA: metal, ceramic alloy, resin wool, polymer, composite fiber, foam plastic, glass sample insulation material, surface), polyurethane, urine cotton, minerals (wool, rock wool, mineral wool board, reinforcement Composite CRC, sandwich concrete, steel glass panel composite material, cement polypaper slate, etc.

Sample requirements

1. Sample state: block, film sample. Only opaque sample is acceptable.

2. Requirements for thermal conductivity samples in the thickness direction: (1) The surface of the sample is flat and the thickness is uniform, and the data of thickness and density should be provided; (2) For cylinder, diameter of 12.7mm or 6mm, the thickness is 1-4mm (for diameter of 6mm,cannot get the specific heat by the comparison method, so the test can only get the thermal diffusivity!!!); (3)For cube, the length and width are 10*10mm, the thickness is 1-4mm; (4) the thermal conductivity is small and the corresponding sample is thinner.

3. Requirements for thermal conductivity samples in the in-plane direction: (1) The surface of the sample is flat and the thickness is uniform, and the data of thickness, density and specific heat need to be provided; (2) The diameter of the sample is 22-25.4mm, the thickness is 0.1-1mm, and the minimum is not less than 20um

Examples

FAQs

Resources